YKYKS/ZKS系列振动筛是专为公路、铁路、建筑用砂石骨料筛分而设计的一种高效型筛机。用于中型和精细筛分作业,为斜面 振动筛,有两层、三层和四层筛面等不同配置。YK/YKS 型筛适用于成品骨料的最终分级筛分。该系列还可以选装高效喷淋系统。

侧板与加强梁、横梁、加强梁之间的连接全部采用钢结构用扭剪型高强度螺栓(抗拉应力为900Mpa),联接强度高,易更换。

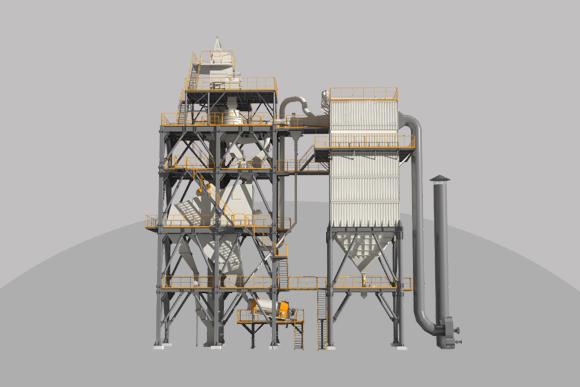

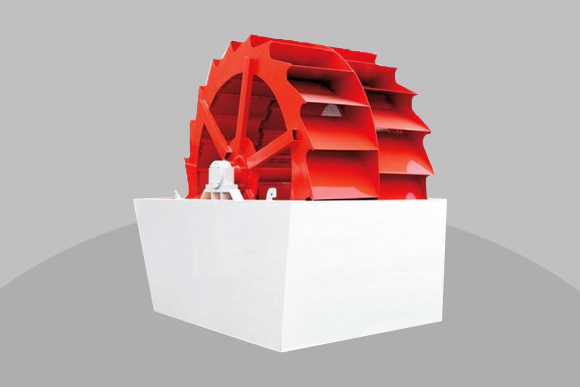

YK/YKS/ZKS系列振动筛图片实拍

性能特点

1、 模块化设计,筛机的零部件种类缩减,筛机维护相当便捷,同时维修点也非常少。

2、 侧板采用整体折弯件,无任何形式的焊点,避免焊接应力造成的开裂。

3、 该产品采用挠性联轴器,电机不参加振动,具有使用寿命长,对振动筛安装条件要求低,振动筛运行平稳、振动轨迹好的优点。

4、YKS 圆振动筛采用国际先进双激振器结构,激振力更强。激振器之间采用同步机构保持激振力一致,结构简单、重量轻、维护方便、使用寿命长。

5、层距大,方便检修、更换筛网

工作原理

振动筛主要由筛箱、筛网、振动器、减振弹簧装置、底架等组成。筛机侧板采用钢板制作而成,侧板与横梁、激振器底座采用高强度螺栓或环槽铆钉连接,采用筒体式偏心轴激振器及偏块调节振幅。振动器安装在筛箱侧板上,并由电动机通过三角皮带带动使激振器偏心块产生高速旋转,产生很大的离心惯性力,激发筛箱产生一定振幅的圆运动,筛上物料在倾斜的筛面上受到筛箱传给的冲量而产生连续的抛掷运动,物料与筛面相遇的过程中使小于筛孔的颗粒透筛,从而实现分级。

技术参数

型号规格 | 筛网层数 | 筛网面积( m) | 振动频率(r/min) | 振幅(mm) | 处理能力 (t/h) | 功率(kW) | 外形尺寸 (mm) |

2YK1548 | 2 | 7.2 | 800-900 | 6/8 | 45-380 | 15 | 5573x2110x1582 |

3YK1548 | 3 | 7.2 | 800-900 | 6/8 | 45-380 | 15 | 5610x2110x1776 |

4YK1548 | 4 | 7.2 | 800-900 | 6/8 | 45-380 | 18.5 | 5798x2110x2191 |

2YK1860 | 2 | 10.8 | 800-900 | 6/8 | 75-600 | 22 | 6596x2510x1583 |

3YK1860 | 3 | 10.8 | 800-900 | 6/8 | 75-600 | 22 | 6759x2510x2008 |

4YK1860 | 4 | 10.8 | 800-900 | 6/8 | 75-600 | 30 | 6828x2510x2375 |

2YK2160 | 2 | 12.6 | 800-900 | 6/8 | 85-700 | 22 | 6596x2810x1580 |

3YK2160 | 3 | 12.6 | 800-900 | 6/8 | 85-700 | 30 | 6765x2810x2025 |

4YK2160 | 4 | 12.6 | 800-900 | 6/8 | 85-700 | 37 | 6912x2810x2380 |

2YK2460 | 2 | 14.4 | 800-900 | 6/8 | 100-800 | 30 | 6693x3110x1587 |

3YK2460 | 3 | 14.4 | 800-900 | 6/8 | 100-800 | 30 | 6758 x3110x2027 |

4YK2460 | 4 | 14.4 | 800-900 | 6/8 | 100-800 | 37 | 6905x3110x2350 |

2YK2475 | 2 | 18 | 800-900 | 6/8 | 130-1000 | 30 | 7942x3120x1578 |

3YK2475 | 3 | 18 | 800-900 | 6/8 | 130-1000 | 37 | 8124x3120x2020 |

4YK2475 | 4 | 18 | 800-900 | 6/8 | 130-1000 | 45 | 8350x3120x2285 |

2YK2675 | 2 | 19.5 | 800-900 | 6/8 | 145-1100 | 37 | 8187x3316x1790 |

3YK2675 | 3 | 19.5 | 800-900 | 6/8 | 145-1100 | 45 | 8305x3316x2215 |

4YK2675 | 4 | 19.5 | 800-900 | 6/8 | 145-1100 | 55 | 8357 x3316x2355 |

2YK3075 | 2 | 22.5 | 800-900 | 6/8 | 165-1250 | 55 | 8229 x3776x1784 |

3YK3075 | 3 | 22.5 | 800-900 | 6/8 | 165-1250 | 55 | 8378x3776x2190 |

4YK3075 | 4 | 22.5 | 800-900 | 6/8 | 165-1250 | 75 | 8465 x3776x2399 |

2YKS3075 | 2 | 22.5 | 800-900 | 8/10 | 180-1850 | 30x2 | 8229x3776x1784 |

3YKS3075 | 3 | 22.5 | 800-900 | 8/10 | 180-1850 | 37x2 | 8378x3776x2190 |

4YKS3075 | 4 | 22.5 | 800-900 | 8/10 | 180-1850 | 37x2 | 8465x3776x2399 |

2YKS3680 | 2 | 28.8 | 800-900 | 8/10 | 220-2100 | 37x2 | 8730 x4380x1990 |

3YKS3680 | 3 | 28.8 | 800-900 | 8/10 | 220-2100 | 45x2 | 8880 x 4380x2390 |

4YKS3680 | 4 | 28.8 | 800-900 | 8/10 | 220-2100 | 45x2 | 8970x4380x2610 |

ZKS1530 | 1 | 4.5 | 800-900 | 8/10 | 80-160 | 3x2 | 3310x2170x1410 |

ZKS1840 | 1 | 7.2 | 800-900 | 8/10 | 120-240 | 3.7x2 | 4420x2480x1680 |

ZKS2050 | 1 | 10 | 800-900 | 8/10 | 200-400 | 18.5x2 | 5518x2710x1815 |