目前现有的人工砂生产线,绝大部分采用湿法生产工艺,不论采用何种机型的洗砂机,其最大的缺点是细砂(0.16mm 以下颗粒)流失严重,有的甚至流失20%以上,这不但损失产量,而且还严重影响砂子的级配,造成级配不合理,细度模数偏粗,大大降低了机制砂的产品质量。过多的细砂排放,还会造成环境的污染。为解决上述问题,我公司研制了细砂回收系统,该系统是本公司吸收国外的先进技术,克服了传统工艺中砂子的洗泥、脱水采用洗砂机,细砂料流失难控制的难题。采用本细砂回收装置能有效的降低细砂的流失,有效地降低尾水中石粉含量,很好地解决了人工骨料加工系统出现的成品砂细度模偏高、石粉含量偏低的难题。

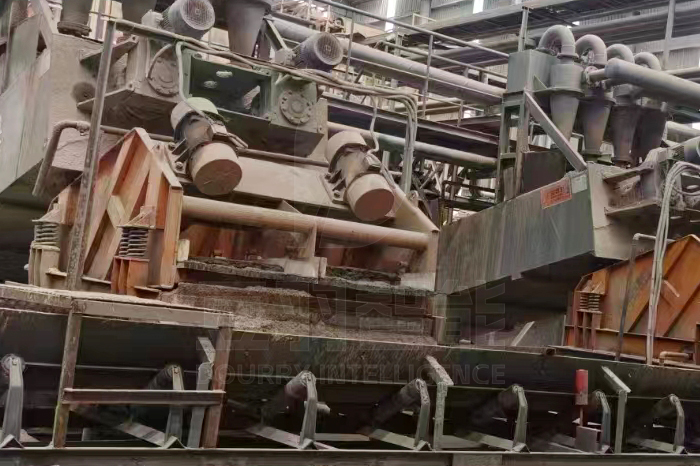

XH系列细砂回收脱水一体机图片实拍

性能特点

1、一机多用,简易操作。兼具脱水回收两大功能,节约成本和占地面积。

2、洗砂干净,回收率高。成品砂二次洗砂脱水,80%-90%细砂回收效果。

3、节能环保,利润可观,兼具环保和经济双重效益。

工作原理

细砂回收脱水一体机由旋流器、溢流水箱、钢丝缠绕管、电机、脱水筛、机架、渣浆泵等组成,在工作时,渣浆泵将筛水混合物输送到旋流器中,细砂经沉沙嘴进入到下方的脱水筛中,经脱水筛脱水后,细砂与水实现分离,剩余的少量细砂和泥等杂质,经过溢流水箱进入污水处理系统,沉淀后进行水资源再次利用。

技术参数

型号 | 旋流器 | 脱水筛 | 处理能力(t/h) | |||

型号 | 泵功率(kW) | 型号 | 材质 | 功率(kW) | ||

XH-1224 | 600×2 | 15×2 | 1200×2400 | 聚氨酯 | 1.5×2 | 50-80 |

XH-1530 | 700×2 | 15×2 | 1500×3000 | 聚氨酯 | 3×2 | 90-120 |

XH-1840 | 700×2 | 18.5×2 | 1800×4000 | 聚氨酯 | 3.7×2 | 170-200 |

XH-2050 | 700×2 | 18.5×2 | 2000×5000 | 聚氨酯 | 18.5×2 | 250-280 |